فهرس الموضوع

In the realm of manufacturing, strategic decision-making is a critical component that can significantly influence the success or failure of an enterprise. The cost of production data serves as a cornerstone for such decisions, providing a factual basis upon which strategies can be developed, assessed, and refined. This data encompasses a wide array of variables, from direct costs like raw materials and labor to indirect expenses such as overhead and maintenance.

Make Production Schedules With Multiple Tools

- By integrating cost of production data into strategic decision-making, companies can create a robust framework for operational excellence and long-term profitability.

- This is the simplest way to account for beginning inventory costs, but not always the most accurate.

- A cost report is not a static document, but a dynamic one that reflects the current status and progress of the project.

- The data should also be categorized and classified according to the cost elements, such as direct costs, indirect costs, fixed costs, variable costs, and overhead costs.

- Conversely, too little WIP might suggest a lack of demand or problems with upstream suppliers.

- The cost of production report first accounts for the number of units in the department’s beginning WIP and transferred into the department during the period.

These metrics help to measure the progress, efficiency, and effectiveness of the cost management and control. For example, a positive CV indicates that the project is under budget, while a negative CV indicates that the project is over budget. Each component plays a vital role in painting a full picture of the production costs. By analyzing these elements, businesses can identify inefficiencies, adjust pricing, and improve their bottom line.

How much will you need each month during retirement?

Between the United States, Mexico and Norway — economic allies to Canada and energy-producing rivals — no production cap has been imposed elsewhere. “We are the only large oil and gas producer in the world to do this,” he told the commons committee. EUs for beginning inventory is the complement of last month’s ending inventory because now you are finishing them up. If domestic partner the beginning work-in-process inventory is 10% done, then the factor to use to calculate EUs to finish it up this month is 90%. Therefore, there are a few more steps in creating the Production Cost Report. Our mission is to empower readers with the most factual and reliable financial information possible to help them make informed decisions for their individual needs.

Introduction to Cost Reporting

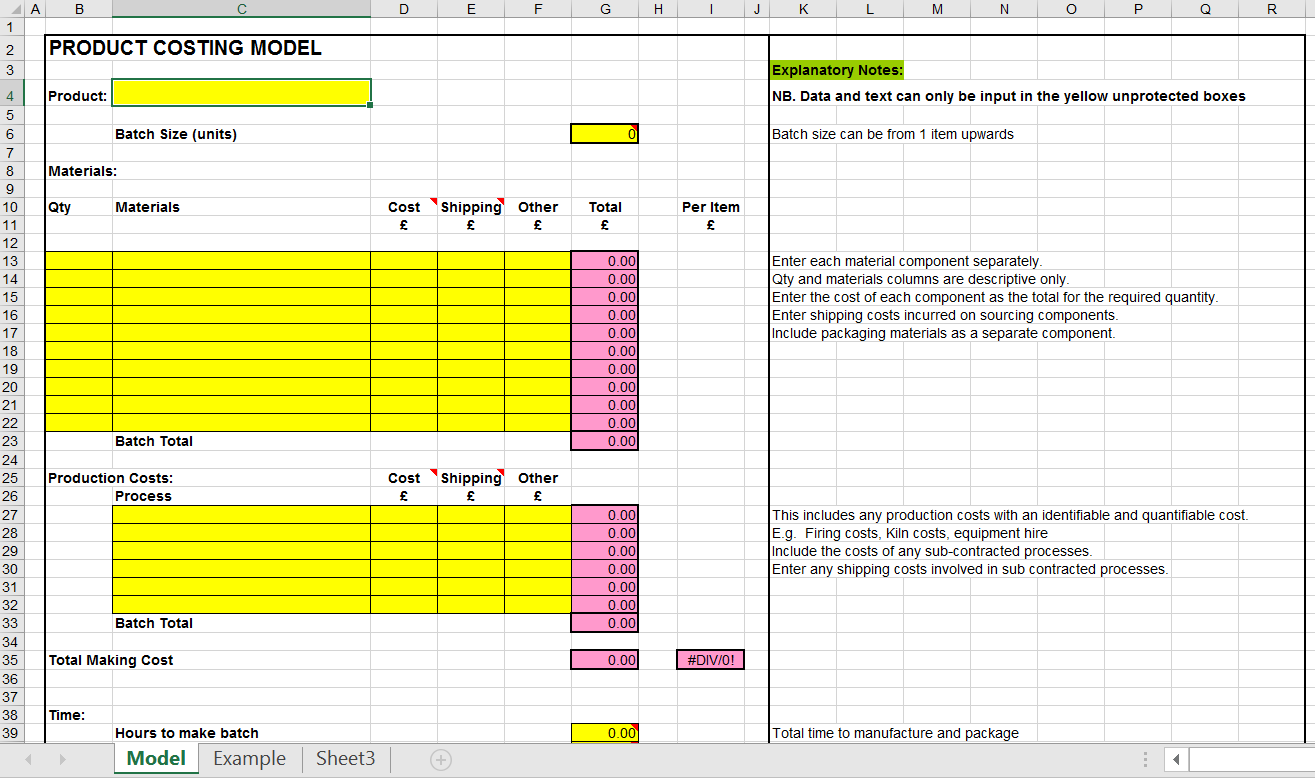

Answering these questions can help to determine the format, structure, and content of the cost report. This means presenting the cost data and metrics in a clear, concise, and consistent manner, using tables, charts, graphs, and narratives. The cost report should follow the standards and guidelines of the organization and the industry, as well as the expectations and preferences of the audience. The cost report should also include a summary, an introduction, a body, and a conclusion, as well as a title page, a table of contents, and an appendix. For example, a cost report for a government contract may have a different format and style than a cost report for a private client.

Beware of Fixed Costs

Auditors examine the methods used to allocate overhead to ensure they are reasonable and consistently applied. From the perspective of a floor manager, the CPR is a tool for day-to-day operational control, ensuring that resources are being used efficiently. For an accountant, it’s a ledger that must balance, reflecting the intricate relationship between costs and output.

The production volume to be manufactured by an organization should be determined by its production budget. It’s a document that includes manufacturing KPIs that allows organizations to track various aspects of their manufacturing process such as for the production volume that’s manufactured over a specific period. To take advantage of this useful manufacturing tool means first understanding what production reporting and a production report are. To make production reports even clearer, we’ll then outline a production report example.

By examining it from various angles and implementing best practices, manufacturers can optimize their operations, reduce costs, and ultimately enhance their market position. The interplay of these factors underscores the importance of a holistic approach to understanding and managing production costs in the manufacturing sector. The production cost report for the month of May for the Assemblydepartment appears in Figure 4.9. Notice that each section of thisreport corresponds with one of the four steps described earlier.

Units started during the period, finished, and then transferred out are 100% complete, so the Equivalent Units and the actual physical units are the same. Under the weighted average method, costs transferred in from last month are added to this month’s costs and distributed across all units. This is the simplest way to account for beginning inventory costs, but not always the most accurate. For example, if costs are going up, the cost of those 750 pie shells in beginning work in process inventory would be less than the cost of the 1,000 pie shells in ending inventory. Production reporting is only one part of the larger production management process. For readers who care to go deeper into the subject, our site is an online hub for all things project management.